- info@cychemicals.com

- +8613655695601

- Weicun Industrial Park, Chunjiang Town, Xinbei District, Changzhou City, Jiangsu Province

Location:Home > Product > Water Treatment Defoamer

Detailed Introduction:

Product introduction

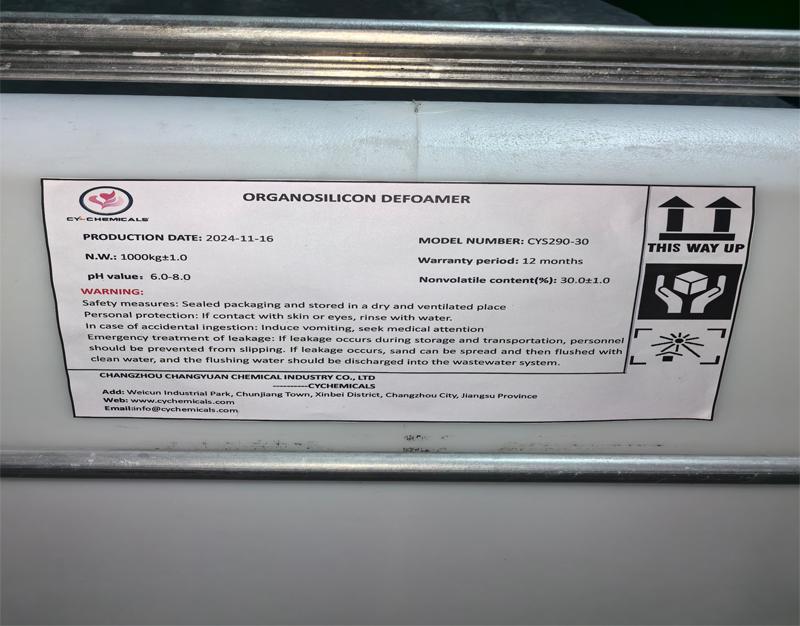

Silicone Defoamer is one of Defoamer for water treatment which is a high content emulsion defoamer. Major recommended industries are sewage treatment, industrial cleaning, etc.

Features

lThe substance components of the antifoam do not contain the substances listed in the SVHC list of the REACH Regulation.

lAntifoaming agent component does not contain NP, APEO.

lThe substance composition does not contain substances contained in the ROHS Directive (Restriction on the Use of Certain Hazardous Substances in Electrical and Electronic Equipment).

lHigh content is more viscous, generally used in special industries, or as secondary dilution raw materials to reduce the cost of use

Silicone Defoamer For Wastewater Treatment - FAQ Guide

1. What Are Silicone Defoamer?

Silicone Defoamer are specialized chemical agents designed to reduce or eliminate foam formation in liquids. Foam, a collection of gas bubbles suspended in a liquid, can cause operational inefficiencies and quality issues in various industrial processes. Silicone Antifoam are composed primarily of hydrophobic silicone compounds, such as polydimethylsiloxane, and are known for their superior performance in foam control compared to non-silicone alternatives.

Key Components of Silicone Defoamer: These include silicone oils, silica particles, and emulsifiers. The silicone oil forms the backbone of the defoamer, while silica particles enhance its foam-breaking properties.

How They Differ From Other Types of Defoamers: Unlike organic or powder-based defoamers, Silicone Antifoam work effectively at low concentrations, resist chemical degradation, and maintain performance under high-temperature and high-pressure conditions.

2. How Does Silicone Defoamer Work?

The mechanism of silicone antifoam revolves around disrupting the stability of foam bubbles.

Mechanism of Action: Silicone Antifoam lower the surface tension of the foam, causing bubbles to collapse. Their hydrophobic properties allow them to spread quickly across the foam surface, expelling trapped air.

Applications in Various Industries: From wastewater treatment to food processing, Silicone Antifoam play a critical role in preventing foam-related disruptions.

3. Types of Silicone Defoamer

Silicone Defoamer come in various forms tailored to specific applications:

Silicone Oil-Based Defoamers: Widely used in industrial processes due to their high performance and stability.

Emulsion-Based Silicone Antifoam: These are water-dispersible, making them ideal for applications in aqueous systems like wastewater treatment.

Self-Emulsifying Defoamers: Offer a balance between ease of use and effective foam control without pre-mixing.

4.Why choose Silicone Defoamer?

Enhanced Efficiency: They deliver fast-acting foam control, even in small quantities.

Versatility: Applicable across a wide range of industries, from manufacturing to food processing.

Environmental Advantages: Many formulations are designed to comply with eco-friendly standards, minimizing environmental impact.

5.Applications of Silicone Defoamer Agents

Role in Water Treatment

Foam in water treatment facilities can obstruct operations and reduce the efficiency of aeration systems. Silicone Defoamer provide an effective solution.

Foam Control in Wastewater Treatment: These agents break down foam caused by biological or chemical reactions, ensuring proper treatment of wastewater.

Prevention of Aeration System Blockages: By minimizing foam, Silicone Defoamer protect aeration equipment, reducing maintenance costs and downtime.

In addition to its application in water treatment, silicone defoamers can also be used in the following industries:

A: Silicone Defoamer in Industrial Processes

Industrial processes often face significant challenges due to foam formation, which can lead to inefficiencies and equipment damage. Industrial Defoamer - Silicone Defoamer are widely used to mitigate these issues.

Manufacturing and Chemical Production: In manufacturing plants, Silicone Defoamer are used in processes like fermentation, polymer production, and chemical synthesis. These agents help maintain smooth operations by quickly eliminating unwanted foam.

Textile and Paper Industries: Foam can hinder dyeing and coating processes in textiles and paper production. Silicone Defoamer ensure consistent product quality and reduce operational disruptions.

B: Use in Paints, Coatings, and Adhesives

Silicone Defoamer are indispensable in industries like paints, coatings, and adhesives, where surface quality is paramount.

Preventing Surface Defects: Foam can cause uneven finishes and pinholes in coatings. Silicone Defoamer help achieve smooth, defect-free surfaces.

Enhancing Application Quality: By eliminating foam during mixing and application, these defoamers improve the overall performance and appearance of the final product.

C: Silicone Defoamer in Food and Beverage

Foam control in food and beverage production is critical to ensure quality and compliance with safety standards.

Regulatory Compliance: Silicone Antifoam used in food applications are formulated to meet strict regulations, such as those set by the FDA and EFSA, ensuring they are safe for use in food processing.

Specific Applications in Food Processing: These include controlling foam in beverage production, frying oil systems, and dairy product processing. By preventing foam formation, manufacturers can improve efficiency and maintain product consistency.

D: Applications in Oil and Gas

The oil and gas sector relies heavily on Silicone Defoamer to maintain efficiency and safety in various processes.

Defoaming Drilling Fluids: Foam in drilling operations can reduce the effectiveness of drilling fluids, leading to operational delays. Silicone Antifoam ensure smooth and uninterrupted drilling.

Processing Crude Oil: During crude oil processing, foam can cause equipment blockages and reduce throughput. Silicone Antifoam effectively address these challenges, enhancing productivity.

6. How to select the Right Silicone Defoamer?

Factors to Consider When Choosing a Silicone Defoamer

Selecting the right Silicone Antifoam is crucial to achieving optimal results.

Application-Specific Requirements: Different industries and processes require tailored formulations. For instance, a water-based emulsion defoamer is ideal for aqueous systems, while oil-based variants work better in non-aqueous environments.

Compatibility with Systems: It’s essential to ensure the defoamer is chemically compatible with the system to avoid unintended side effects, such as residue formation or reduced efficacy.

7. How to use the defoamer and antifoam?

Getting the most out of Silicone Antifoam involves following best practices:

Correct Dosage: Using the right amount of defoamer is key. Overdosing can lead to residue issues, while underdosing may fail to control foam effectively.

Best Practices for Application: Silicone Antifoam should be added at the right stage of the process. For example, introducing them early in a batch process can prevent foam formation, rather than dealing with foam after it occurs.

8. Sustainability and Environmental Impact

Advances in Eco-Friendly Silicone Defoamer

The push for sustainability has led to significant innovations in Silicone Antifoam formulations.

Biodegradability Improvements: We are developing defoamers that break down more easily in the environment, reducing their ecological impact.

Compliance with Environmental Standards: Many modern defoamers meet stringent global environmental regulations, making them suitable for use in eco-sensitive industries.

Conclusion

Silicone Defoamer are vital for industries ranging from manufacturing to food processing. Their unparalleled efficiency, versatility, and adaptability make them an indispensable tool for foam control. As the industry moves towards sustainability, eco-friendly formulations and innovative technologies promise to redefine the future of silicone defoamers. Understanding their applications, benefits, and limitations is key to leveraging their potential effectively.

Previous : Silicone Based Defoamer